Ceiling Grid: Understanding the Specifications that Determine Quality

When it comes to ceiling grid systems, many customers focus on what they can see — clean lines, neat finishes, and a seamless tile installation. But what really determines the performance and longevity of a ceiling grid is what cannot easily be seen.

A ceiling might look flawless on day one — smooth tiles and perfect alignment. But if the grid beneath is of inferior quality, cracks, sagging, corrosion, or even collapse could follow. That is why the specifications of the grid are critical to long-term performance.

Unfortunately, price often becomes the main driver in the decision-making process. Too often, cheaper alternatives are compared to premium solutions without understanding the real differences in quality. Knowing what to look for and why it matters will help ensure that a ceiling installation is not compromised by structural weakness in the grid.

The Role of Steel Grade in Ceiling Grids

The steel used in the grid system forms the backbone of the ceiling. Its quality directly impacts strength, durability, and resistance to wear and corrosion.

What is ISQ300 Steel?

ISQ stands for International Standard Quality, and ISQ300 is a cold-rolled mild steel specification commonly used in applications that require forming, bending, and punching, such as ceiling grids.

The “300” refers to its minimum yield strength of 300 MPa (megapascals), providing an excellent balance of strength and formability. This means the steel can withstand substantial stress before deforming, offering the ideal balance between strength and workability — making it perfect for ceiling grids that need both performance and precision.

Why Steel Quality Matters

Poor-quality steel in ceiling grids can lead to:

- Sagging or deformation over time, especially under load or in humid environments

- Corrosion and rust, reducing strength, stability and service life

- Installation issues, such as brittleness or inconsistent forming

By using ISQ300 steel, our premium grid systems deliver:

- High dimensional accuracy and consistency

- Superior corrosion resistance, especially when paired with quality zinc coating

- Long-term durability, even in demanding environments

- Ease of installation, thanks to precise forming and clean punching

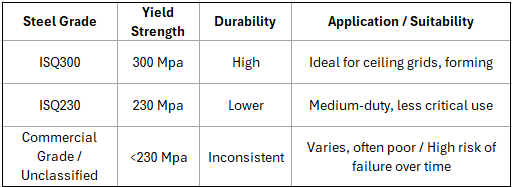

Comparing ISQ300 to Lower-Grade Steels

SABISA recommends a minimum of ISQ230. Lower-grade steels may appear more affordable, but in the long term they compromise both safety and aesthetics.

Steel Gauge in Ceiling Grids: Why Thickness Matters

Understanding Steel Gauge

Steel gauge refers to the thickness of the steel sheet from which the ceiling grid is manufactured. This thickness directly impacts the grid’s ability to:

- Carry the load of ceiling tiles and services such as lights, air vents, and sprinklers

- Maintain straightness and alignment without bending, twisting, or deflecting

- Withstand the stresses of installation and long-term use

The Main Tee: The Structural Backbone

The Main Tee is the primary load-bearing profile in a suspended ceiling. It supports the weight of the Cross Tees, and the ceiling tiles themselves. If the Main Tee is manufactured from thin or low-grade steel, the entire ceiling structure can be put at risk. Problems such as sagging, warping, and even partial collapse may occur, especially in environments with added loads like air-conditioning vents or heavy tiles.

Our ceiling grids are manufactured from steel no thinner than 0.30mm.

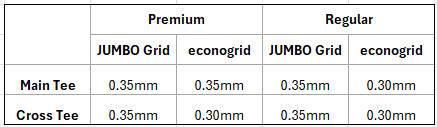

Steel Gauge Summary for JUMBO and econogrid Systems

This 0.30–0.35mm gauge range provides:

- Structural integrity: confidence that the ceiling will remain stable and aligned for years

- Safety: resistance to sagging or failure under load

- Professional finish: clean, straight lines that enhance the overall aesthetic

While steel grade determines strength, the thickness of the steel (gauge) is equally important in ensuring the grid can safely support the ceiling load.

Zinc Coating: Protection Against Corrosion

Along with steel grade, zinc coating thickness is another critical factor. In coastal regions with high humidity, a zinc coating of Z100 is recommended for maximum corrosion resistance. Inland, a lighter coating such as Z60 may suffice. Site conditions should always be considered.

We have introduced a Z60 zinc coating option in both our econogrid and JUMBO Grid ranges for use in low-humidity areas.

Beyond steel grade, gauge, and zinc coating, certain design details further enhance performance and cost efficiency:

- Stitching method: improves joint strength and durability

- Clips: Standard Clips are more economical, while Quick Release Clips provide faster installation

- Fire punchouts: allow controlled expansion of the grid during a fire, delaying collapse and improving safety

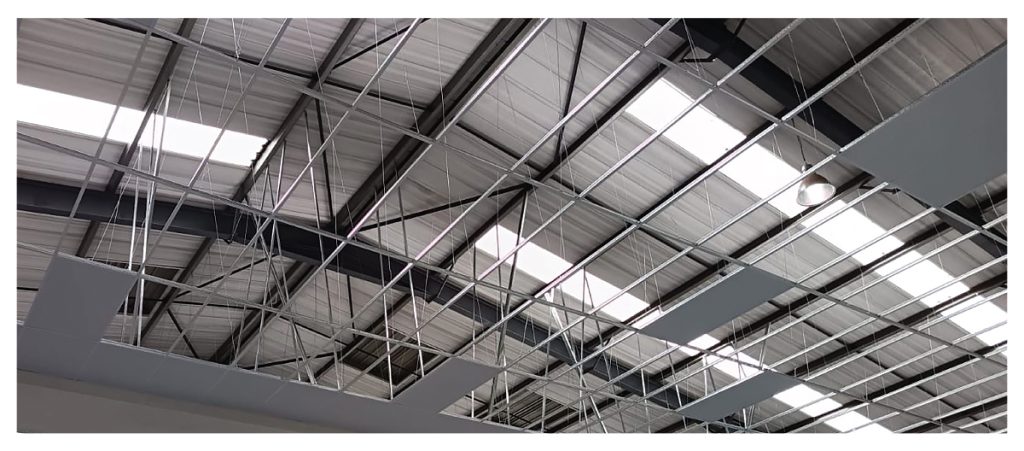

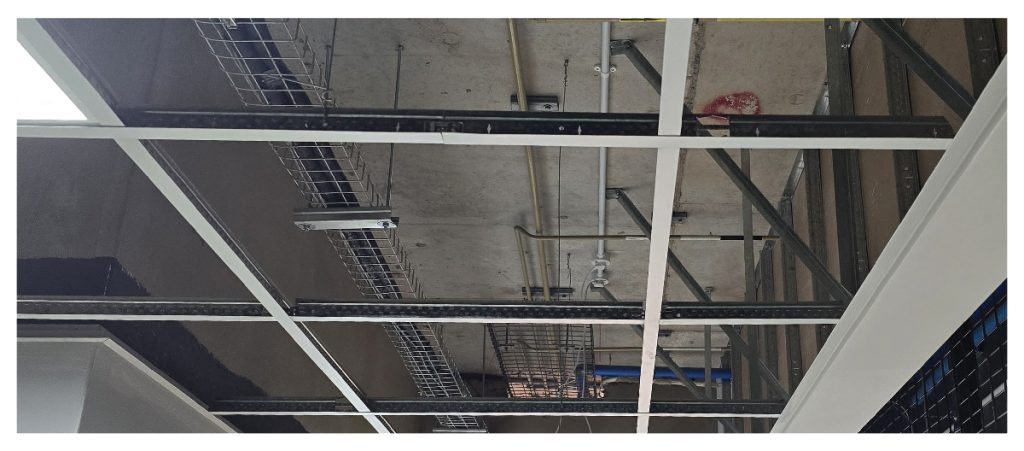

JUMBO Grid Ceiling Installation where you can see the stitching and the product identification. Z60 is stamped on all Z60 JUMBO Grid.

Our Commitment to Quality

At Pelican Systems, we do not compromise on the quality of our grid systems. Both JUMBO and econogrid — in Premium and Regular ranges — are manufactured in accordance with ASTM C635 and SANS 10400 standards for ceiling suspension systems.

The Regular ranges provide a cost-effective option, offering around a 10% saving and can be used if site conditions allow.

When installing a ceiling, it’s essential to have peace of mind that the structure will last. Our JUMBO Grid and econogrid are manufactured to stringent specifications, ensuring strength, accuracy, and safety in every installation.

Together with our Ceiling Grid Manufacturer, Pelican Systems offers a 10-year performance warranty on our Premium Grids and 5-Years for the Regular Grid systems — offering complete peace of mind.

At the end of the day, a ceiling is only as strong as the grid that supports it.

When installing a ceiling, it’s essential to have peace of mind that the structure will last.

Selecting the right steel grade, gauge, and zinc coating is the foundation of structural integrity, safety, and a ceiling that looks good — and lasts — for years.